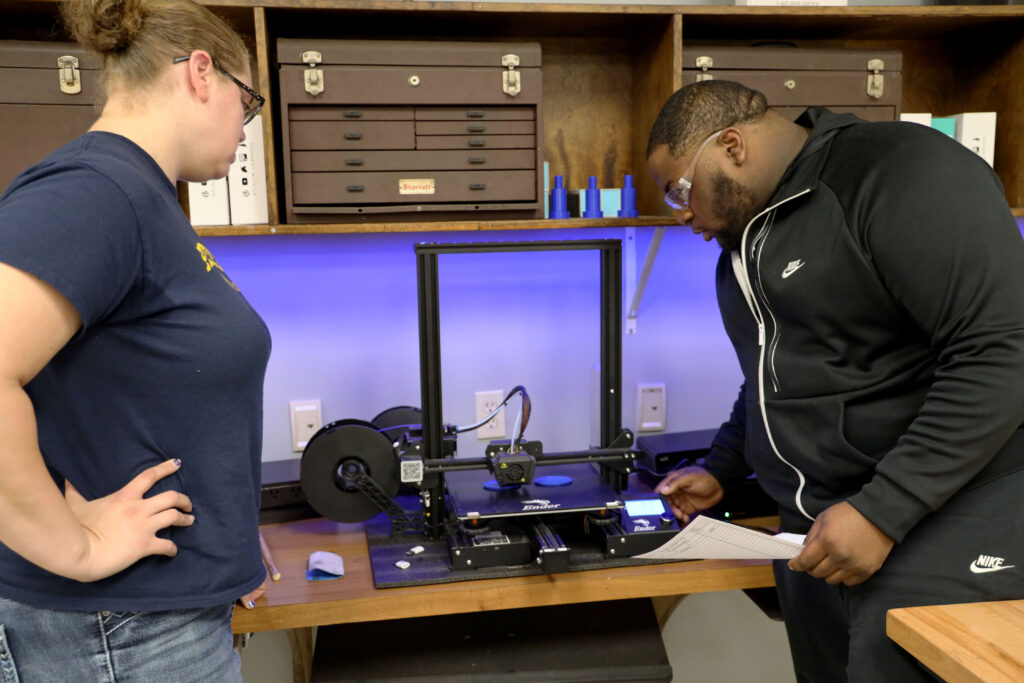

BRTC Machine Tool and Technology students Krystina Compton use a 3D printer to make the first prototype of Nubbins prosthetics

The Black River Technical College(BRTC) Machine Tool Technology (MTT) program is currently working on the first prototype for Greene County Animal Farm rescue puppy Nubbins prosthetics.

The new set of paws will consist of ventilation holes, joint tolerances, and ergonomically correct padding, which will improve Nubbins movement and grip.

Though the students are currently making the first prototype, several more will be made before Nubbins comes back for a fitting, as there will surely be kinks to work out in the design, as no two are the same due to the measurements of the dog, said MTT Instructor Rick Barker.

“We are very excited to see Nubbins again for his measurements and proud we can help him. All of the students are very invested in this project,” Barker added.

BRTC MTT students working on the project are team leader Jakob Barnhill, Krystina Compton, Jonathan Moody, Jywon Green, and Hank Dubois.

Six-month-old Nubbins was either born with both of his front legs deformed or was in an accident (rescuers weren’t sure as they received him after birth) causing him to have trouble getting around. The BRTC MTT students will manufacture, from scratch, prosthetics that will fit on his front legs.

According to rescuers at the Animal Farm, Nubbins deformity makes it especially hard for him to roam freely outdoors due to the tenderness of the skin on his front legs. So, he lives a life indoors. The MTT students hope to make it where Nubbins can live a more normal doggy life with his new prosthetics. The project should be finished in late April or early May, Machine Tool Technology Instructor Rick Barker said.

Nubbins is waiting for his fur ever home and currently resides at the Greene County Animal Farm that can be contacted at (870)240-8117 or via Facebook.

The Machine Tool Technology program consists of a wide variety of machining. Machinists and Toolmakers design and create prototypes, fixtures, jigs, and tooling/dies from which most metal and other manufactured items are made, which includes large heavy machinery to small hand tools. Working in a modern, fully-equipped machine shop, students in the machine tool technology program gain the knowledge and skills needed to cut, machine, mill/turn, metals and 3d print polymers/carbon/onyx when regarding NIMS assigned projects.

This high-precision trade requires development of high demand skills in the use of hand tools, precision measuring instruments, testing equipment, and basic, automatic, and computer-numerically-controlled (CNC) machine tools and programming. The program also covers heat treating tool steel and alloying material, as well as accident prevention, leadership, and quality control.

For more information on BRTC”s Machine Tool Technology program contact Rick Barker at (870)248-4139 or email him at rick.barker@blackrivertech.edu.